Viton Shelf Life

Apr 5316 is often used as a guideline in determining useful shelf life of elastomers used in other industries.

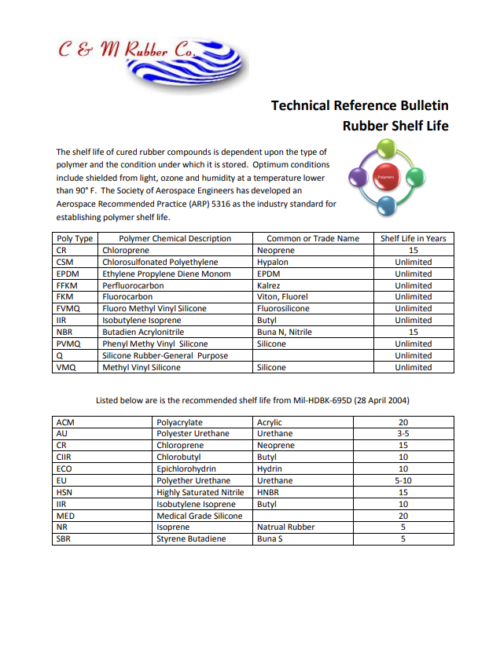

Viton shelf life. Global o ring and seal adheres to the sae international aerospace standard as5316 for all elastomer product shelf life and storage conditions. If the shelf life has expired products should be carefully evaluated for possible use as originally intended before discarding products solely based on the suggested shelf life. Viton fkm 20 years hypalon csm 5 10 years neoprene cr 5 10 years e pdm epdm 5 10 years butyl iir 5 10 years nitrile. The society of aerospace engineers sae issued aerospace recommended practice arp 5316 was issued in 1998 to supercede mil hdbk 695c canceled as the aerospace industry standard.

There can be some confusion between the difference between the service life of a rubber part and its. O ring shelf life compliance standard. Unless compliance regulated shelf life of all rubber parts should be considered unlimited. Shelf life guideline these numbers represent average shelf life under normal dry cool storage conditions away from direct sun uv rays and should be used for guidance reference purposes only.

Shelf life of rubber products. Elastomer and o ring shelf life is governed by sae international standard arp5316d that calls out all aspects of o ring shelf life. Table of elastomer shelf life recommendation. Elastomer and o ring shelf life recommendation summary with proper storage.

Key elements of the arp5316d standard include. Viton freeflow extrusion process aids also improve processing increase output and reduce waste. Elastomers are susceptible to deterioration by aging. Sae arp5316 is the most widely referenced guide for data recording procedures packaging and storing of aerospace elastomeric seals.

Shi hwang is the technical director at warco biltrite. Arp5316 can be a useful guideline for companies who don t have a recommended shelf life control on elastomeric. Products made with viton fluoroelastomers retain their flexibility shape and seal when exposed to chemicals and high temperatures. The rate of deterioration depends on a number of factors temperature store between 15 25 c 59 77 f and away from direct heat sources light avoid exposure to direct sunlight artificial light or uv humidity below 65 recommended.

Experience demonstrates that storage conditions impact the useful life of o rings than generalized shelf life time. Previously known as arp5316 recommended practice this standard is based upon both cumulative studies and industry input regarding practical storage limits and fifo requirements. Shelf life vs service life. Temperature o rings need to be stored below 100f 38c and stored away from direct sunlight and sources of heat radiators heaters boilers and above 59f 15c.